X-Ray Computed Tomography is a non-destructive imaging technique used for the complete inspection of workpieces.

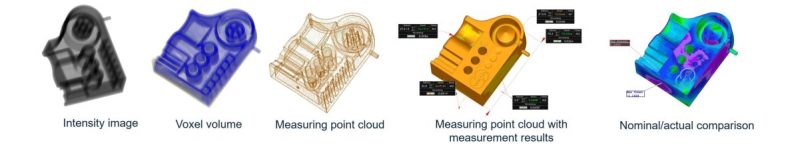

The system operates in a way where a series of X-Ray images are computationally reconstructed to generate a three dimensional representation of the workpieces complete geometry. The physical characteristics of X-rays allows for visualisation of both internal and external geometry, facilitating the detection of voids / cracks inside of the part – deformities otherwise undiscoverable without destructive testing.

In 2005 at the Control Fair in Germany, Werth introduced the first Co-ordinate Measuring Machine (CMM) utilising CT technology. For the first time, it was possible to measure accurately and repeatably the internal and external geometry of a measurand. Werth Computed Tomography systems are calibrated in such a way the measurements taken are traceable to the international standard allowing for such a system to handle entirely the inspection process, with respect both to automatic measurement and automatic detection of deformities such as voids / cracks / burs. This completely removes the necessity to destroy workpieces in order to comprehensively inspect a workpiece.