When manufacturing plastic workpieces using the injection moulding process, measurements close to production at high measuring speed are advantageous. In multi-shift operation and for 100% measurements in the line, high availability is another decisive criterion for the selection of the coordinate measuring machine. By customising the combination of basic devices and components, measuring systems with computed tomography can be adapted to the respective application.

Coordinate measuring machines for different requirements

Plastic workpieces are often produced in multi-layer operation using tools with 64, 128 or even 192 nests. Examples of this include plastic gears, rollers in drawer systems from the furniture fittings industry and screw caps for disposable or reusable plastic bottles. The workpieces from the nests of all the tools running in the injection moulding machines are measured once or several times per shift. A high measuring speed and high availability are crucial for this high throughput, as all workpieces produced during the measurement represent potential rejects in the event of mould wear with subsequent burr formation, for example.

Transmission sources achieve a measuring speed 5 times higher than that of coordinate measuring systems with reflection sources. The high measuring speed requires good exposure due to the high power of the X-ray source. Transmission sources have a small focal spot even at high power and therefore sufficient resolution to automatically detect burrs, for example. Werth long-life transmission sources in particular offer high availability, where annual maintenance is sufficient, as with conventional coordinate measuring machines. In addition, maintenance by the operator, for example a regular filament change, is no longer necessary.

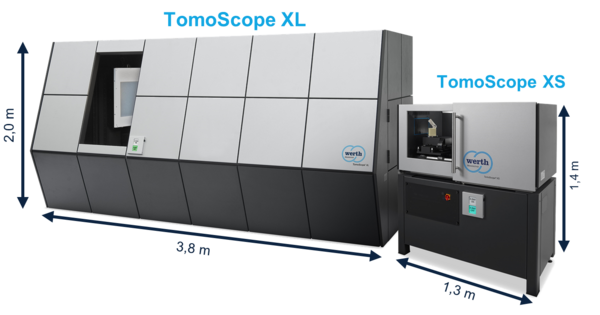

The modular device design allows the measuring speed or resolution to be optimised, for example. Various basic device sizes are combined with different X-ray components for this purpose. With small measuring systems such as the Werth TomoScope XS, a larger proportion of the radiation energy reaches the detector as it is located close to the X-ray source. This results in bright images with correspondingly short measurement times. The use of high-resolution long-life transmission sources with high power also contributes to the good exposure. With X-ray voltages of 130 kV, 160 kV or 200 kV, not only plastic workpieces but also medium-sized metal-composite workpieces can be penetrated by the X-rays. In order to achieve a high resolution, a detector with many small pixels is also required, for example 3000 pixels with a pixel size of 50 µm.

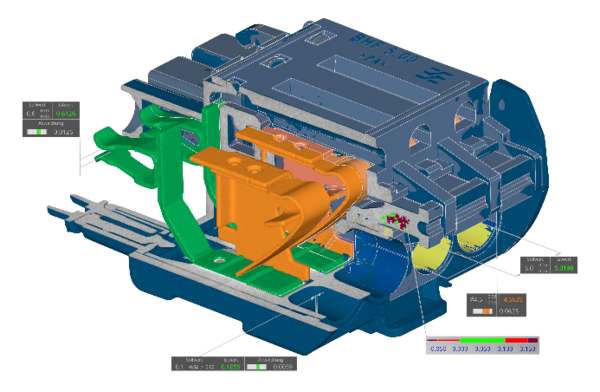

To optimise the resolution, basic devices of different sizes are used with transmission sources that are available with X-ray voltages of up to 300 kV. With the high X-ray voltages and small focal spots, the measurement of large and dense workpieces with high resolution is possible. For particularly high resolution requirements, sub-microfocus sources with additional focussing of the electron beam and correspondingly small focal spots can be used. When selecting the detector, large measuring ranges with high resolution and a good price-performance ratio or, optionally, short integration times are important. For example, the TomoScope S Plus with an X-ray voltage of 200 kV and a detector with 2500 pixels and a pixel size of 124 µm is used for the measurement of large plastic housings. The same basic device can be used for the measurement of connector strips for e-mobility. For larger workpieces that are difficult to penetrate, a higher X-ray voltage of 240 kV and a larger detector with a similarly high pixel size are used.larger detector with a similarly high resolution of 3000 pixels and a pixel size of 140 µm.