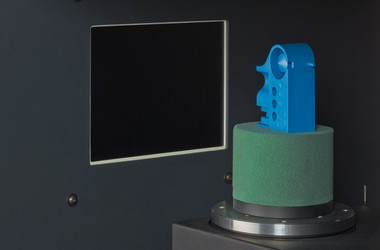

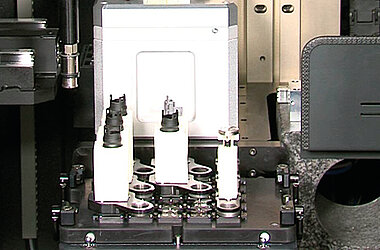

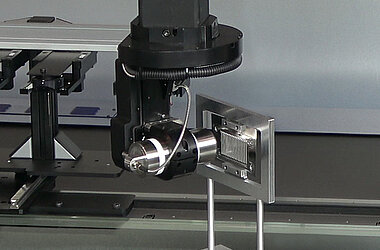

By combining transmission tubes with 225 kV acceleration voltage and large, high-resolution detectors, the TomoCheck ® S HA (High Accuracy) enables 3D measurements of multi-material assemblies as well as large-volume workpieces with high resolution and unprecedented accuracy. The basic design of the computed tomography coordinate measuring machine in granite, high-precision machine mechanics and air bearing technology enable length measurement errors in the sub-micrometre range. Areas of application are micro-parts as well as workpieces made of plastic, light metal and graphite.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-hub connections

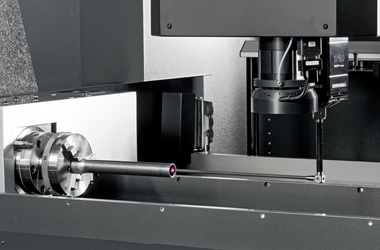

- Shafts and axes

- Workpieces with micro-features

- Workpieces with optical functional surfaces

- Tools with geometrically determined cutting edges

- Tools with geometrically indeterminate cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Products

-

Service

- Programming services

- Measuring machine capability analysis, measurement process capability and traceability

- Measurement services with multi-sensor systems or computed tomography

- Repair

- Maintenance

- Calibration

- Installation, relocation and commissioning

- Retrofitting and updates

- Training courses

- Downloads

- About Werth

- Careers

- Foundation

- Publications

- Downloads