Due to the growing requirements for e-mobility, 100 % inspection is increasingly necessary.

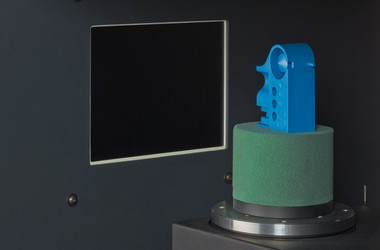

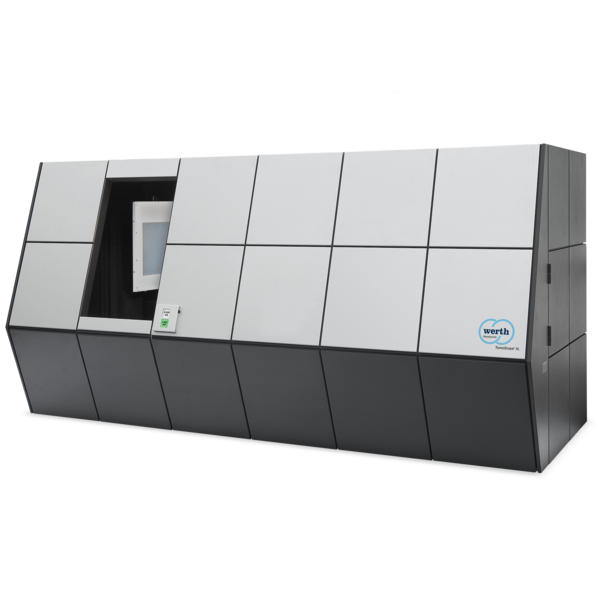

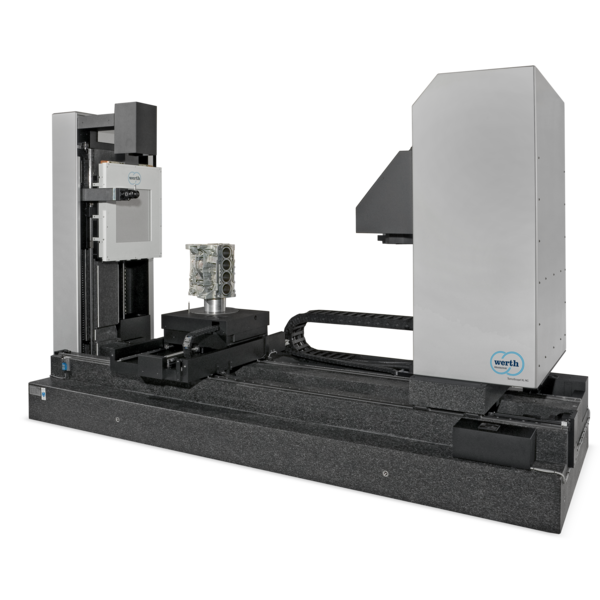

With a TomoScope® XS Plus, a Werth longlife transmission source and Werth contour image processing, the geometrical characteristics such as deformations of the electrode winding of the anode and cathode can be measured reliably in just a few seconds.

Metallic particles introduced during the production process are automatically recognised in just a few seconds to prevent short circuits and thus possible fires in the entire high-voltage storage system.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-hub connections

- Shafts and axes

- Workpieces with micro-features

- Workpieces with optical functional surfaces

- Tools with geometrically determined cutting edges

- Tools with geometrically indeterminate cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Products

-

Service

- Programming services

- Measuring machine capability analysis, measurement process capability and traceability

- Measurement services with multi-sensor systems or computed tomography

- Repair

- Maintenance

- Calibration

- Installation, relocation and commissioning

- Retrofitting and updates

- Training courses

- Downloads

- About Werth

- Careers

- Foundation

- Publications

- Downloads