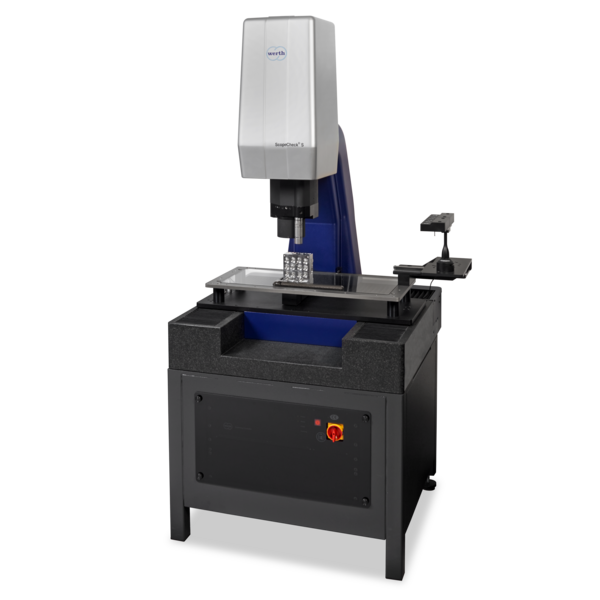

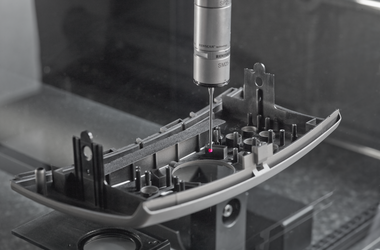

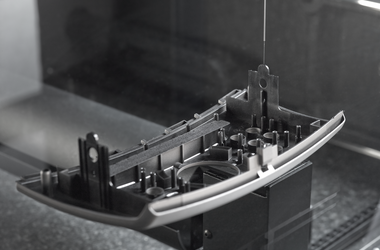

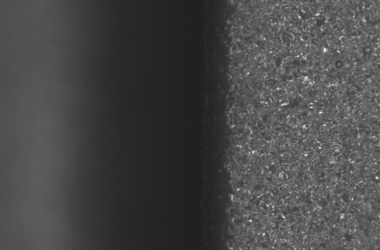

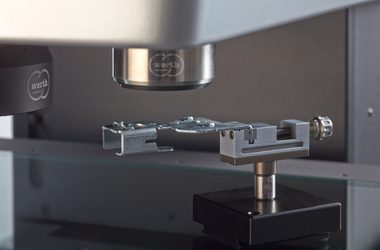

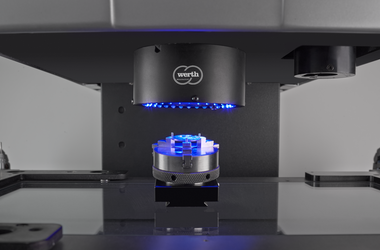

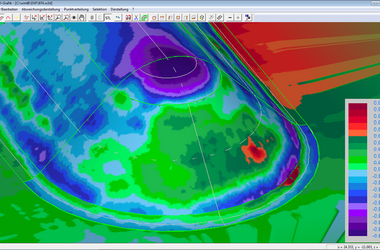

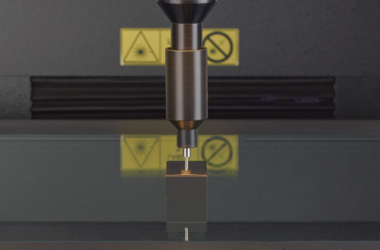

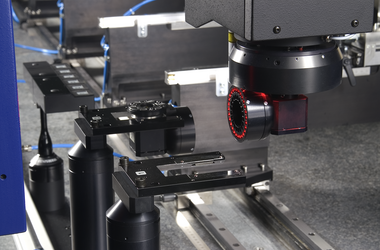

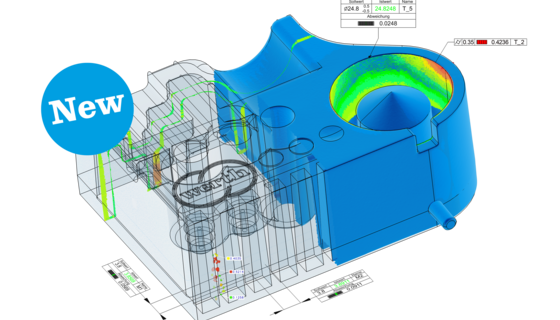

The compact ScopeCheck® S has an extremely robust design made of granite and polymer concrete with protected guideways and scales as well as temperature compensation and has therefore been optimised for use close to production. The Werth image processing sensor included in the basic configuration is specially tailored to the requirements of dimensional metrology and provides reliable Edge Finder even in the most difficult contrast conditions. Different focus variation methods enable optical 3D measurements. Typical areas of application are turned, milled, plastic, punched and bent parts.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

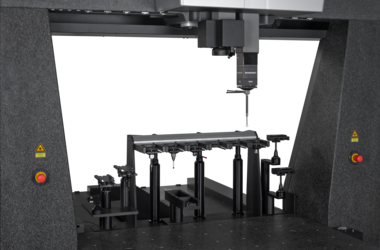

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-hub connections

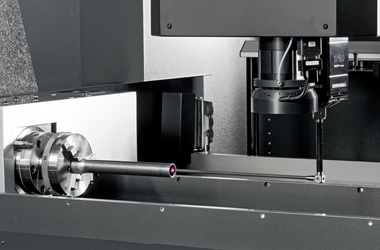

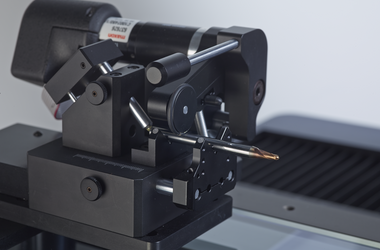

- Shafts and axes

- Workpieces with micro-features

- Workpieces with optical functional surfaces

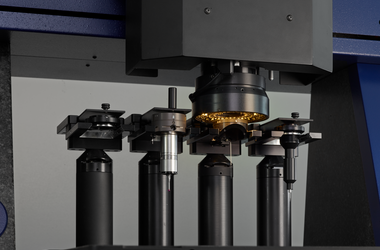

- Tools with geometrically determined cutting edges

- Tools with geometrically indeterminate cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Products

-

Service

- Programming services

- Measuring machine capability analysis, measurement process capability and traceability

- Measurement services with multi-sensor systems or computed tomography

- Repair

- Maintenance

- Calibration

- Installation, relocation and commissioning

- Retrofitting and updates

- Training courses

- Downloads

- About Werth

- Careers

- Foundation

- Publications

- Downloads